Warehouse Management System (WMS) Guide

In this detailed guide, we will explore every aspect of the system for warehouse management. We will also explore the key features, their potential benefits, and top WMS systems.

Did you know that inefficient warehouse management can cost businesses up to 10% in lost revenue? This demonstrates the significant need for warehouse management systems. Using the WMS system, businesses can increase visibility in inventory, optimize the material flow, boost labor efficiency, and maximize storage utilization.

According to a report, around 80% of businesses experience significant improvement within the first years. A warehouse management system helps businesses optimize inventory, fulfill orders, enhance visibility across the supply chain, and automate routine tasks.

This chapter will explore the definition, why it matters for businesses, and the challenges with traditional warehouse management.

Supply chain management (SCM) is the process of managing the flow of goods, data, and finances from the start of a product's life cycle to its delivery to the customer. It involves activities including sourcing raw materials, design, production, warehousing, shipping, and delivering finished products to customers.

A Warehouse Management System (WMS) is software that helps businesses optimize their day-to-day warehouse activities. Its capabilities also extend to the supply chain process, allowing companies to track inventory, pack, ship, and deliver orders, receive incoming shipments, and manage warehousing and distribution tasks.

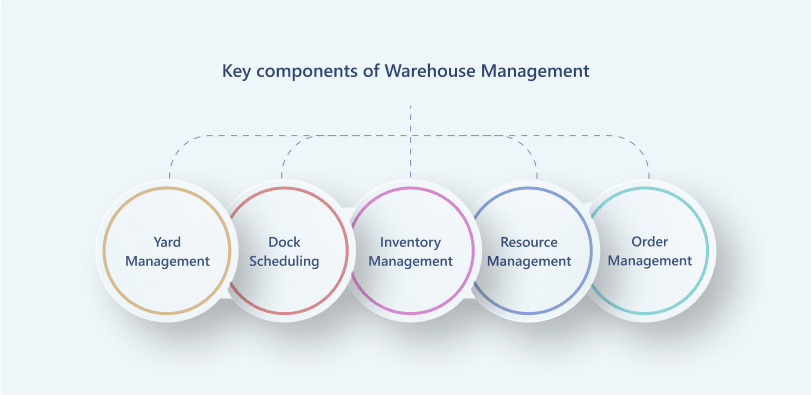

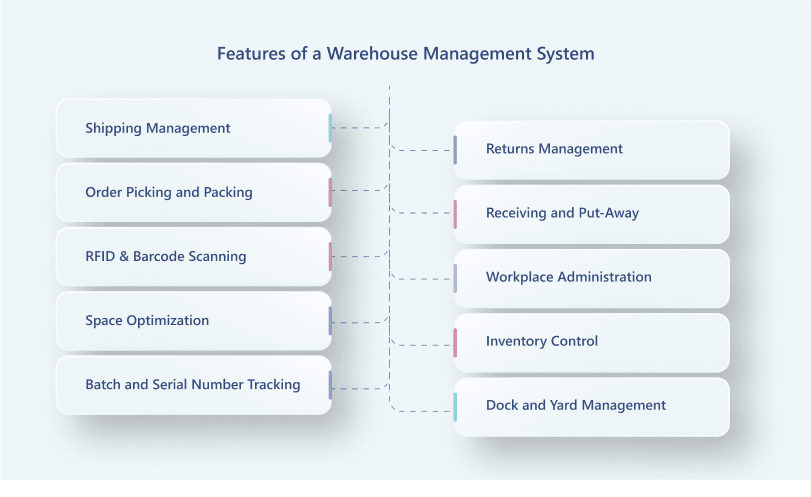

The system for warehouse management provides tools that help businesses in yard management, dock scheduling, inventory management, resource management, order management, and much more. This ensures that the right things are available at the right time, quantity, and location.

At its core, a WMS warehouse management integrates several processes formerly completed by hand or by several systems, like receiving items, allocating storage locations, and keeping inventory levels. WMS systems use cutting-edge technologies to handle orders accurately and efficiently, including barcoding, RFID, and AI-driven analytics.

Error Reduction

Errors in any operation can lead to increased costs and customer dissatisfaction, particularly for warehouse operations. For instance, a customer receives incorrect items, or an order gets delayed because of errors in inventory management.

These errors can damage credibility and result in missed sales. Businesses can utilize WMS, which enables methodical procedures and checks, reducing errors.

For instance, warehouse management system software includes barcode scanning, guaranteeing that the correct products are chosen and dispatched. Additionally, it automates inventory adjustments, reducing the likelihood of stock discrepancies. These features improve overall accuracy while also cutting down on the amount of time spent on manual corrections.

Improved Efficiency

Order fulfillment, storage, and receiving are just a few processes that are streamlined by the warehouse stock management system, improving workflows. Advanced WMS systems minimize the time spent touring the warehouse using algorithms to identify the most effective picking routes.

For instance, an employee may concurrently conduct inventory counts in the same aisle while selecting things for an order. With this optimization, companies can manage increased order volumes without incurring higher labor expenses.

Real-Time Decision-Making

Warehouse managers can track order statuses, monitor inventory levels, and spot bottlenecks early on. Redirecting resources to high-priority work or resolving delays before they worsen are examples of proactive decision-making made possible by this instant visibility.

For instance, managers can swiftly modify replenishment schedules to avoid stockouts if a WMS warehouse management notices an unexpected rise in requests for a specific product. On the other hand, it can assist companies in avoiding overstocking and saving on carrying costs by identifying slow-moving goods.

Cost Savings

Although an upfront cost is associated with a warehouse management system implementation, it significantly reduces long-term costs. Firms can attain significant operational efficiency through labor optimization, error reduction, and inventory management improvements.

For example, accurate inventory management reduces storage and obsolescence costs by reducing overstocking and understocking costs.

In order to maximize space utilization, advanced systems employ slotting optimization to identify the ideal product storage locations depending on size, demand, and picking frequency. This maximizes the capacity of available spaces and lessens the demand for extra storage facilities.

Integration with Other Systems

A management system for a warehouse works in tandem with other business systems, including CRM Systems, ERP , and Transportation Management Systems (TMS). Data flows smoothly across the supply chain because of this interconnection.

For instance, interaction with a TMS simplifies shipping and logistics, while interaction with an ERP system improves demand planning and financial management.

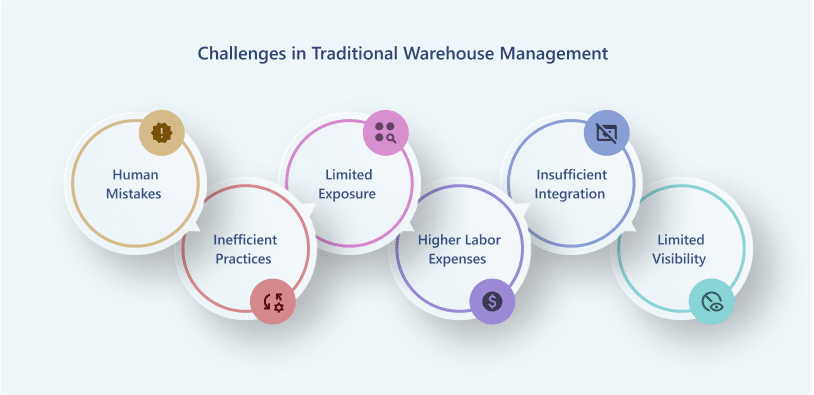

Human Mistakes

Conventional businesses employ error-prone manual data entry and paper-based inventory tracking. Inaccurate stock levels, poor order fulfillment, and misplaced goods are a few of the errors. Delays and increased operating costs were the results of these mistakes.

Inefficient Practices

Without proper standardized procedures, businesses need to spend time on repetitive tasks, shoddy storage layouts, and item searching. This process lowers the lowered throughput and overall productivity.

Limited Exposure

Without real-time data, managers found it challenging to obtain a precise picture of inventory levels and warehouse operations. This leads to operation on judgment, which results in stockouts, overstocking, and lost sales opportunities.

Higher Labor Expenses

Managing inventory counts, order picking, and shipping duties required a sizable workforce due to the labor-intensive nature of manual processes. Due to the dependence on human labor, processes became less efficient, and costs went up.

Insufficient Integration

The supply chain management SCM software combines various processes, and businesses use fragmented systems to manage them. These create silos and result in poor communication between departments. For example, incomplete stock information across departments may arise from delays in updating inventory levels.

Limited Visibility

Managers frequently find it difficult to precisely assess inventory levels and warehouse activities when using the old way. Stockouts, overstocking, and lost sales opportunities result from your inability to make well-informed decisions due to this lack of visibility.

This chapter will explore the top ten features of warehouse management systems that are crucial for seamless operation.

The outstanding shipping feature is a must for a business to guarantee precise and prompt delivery. The system for warehouse management helps companies automate and optimize the order fulfillment process, helping to process the orders quickly and deliver the products to customers rapidly.

Warehouse management system software provides various features for effortless shipping, such as shipping label integration, document production, automated service selection, and coordination with last-mile delivery.

For instance, you can generate bills of lading, packing lists, and shipping labels with minimal human input. In addition, warehouse management systems also integrate with the transport management system to optimize the delivery route and time, along with real-time shipment tracking.

The effectiveness of a warehouse can be determined by how efficiently orders are picked and packed. A warehouse inventory management system guarantees accuracy and speed by employing sophisticated algorithms to recommend the best picking routes and save transit time inside the warehouse.

Features like zone, batch, and wave picking allow companies to tailor operations to meet their requirements. Furthermore, automated pallet or box size suggestions based on order volume speed up packaging and ensure cost-effective shipping.

For example, adding mobile devices or wearable scanners simplifies these processes even more, reducing human error and boosting output, which benefits both the business and its customers.

Businesses require accurate inventory tracking, which is possible through RFID and barcode scanning. With these technologies' help, you can instantly capture and transfer the inventory, guaranteeing inventory accuracy and traceability.

RFID enables bulk reading without requiring a direct line of sight. This improves inventory forecasting and lowers losses by making receiving and shipping considerably quicker and more precise.

In addition, barcodes and RFID tags also provide you with real-time updates about your inventory. Warehouse management system software integrates with this technology to ensure faster stock updates, decrease errors, and eliminate manual data entry.

For instance, as soon as an item is scanned, its location, status, or movement is updated in the system.

Any warehouse needs space, and WMS warehouse management makes sure that every available inch is used effectively. The system uses sophisticated algorithms to recommend the best inventory slotting based on customer demand trends, item size, and movement frequency.

Dynamic storage options, like assigning fast-moving goods to easily accessible locations, reduce handling time and increase operational efficiency. Moreover, the warehouse stock management system can also forecast future space requirements, helping businesses plan.

Imagine fewer bottlenecks and faster workflows simply by making smarter use of your existing space—no expensive warehouse expansions needed.

Batch and serial number tracking are crucial for businesses, as they offer product traceability. You can give unique identification to every product or batch using an inventory management system for warehouse.

A system for warehouse management can track product origin, condition, and movement throughout the supply chain and guarantee complete visibility from receipt to shipment. This feature is essential for managing recalls, quality assurance, and compliance.

WMS is able to promptly detect item flaws, for instance. You can isolate the impacted units if the defect is found in a particular batch.

Returns are an inevitable part of any business, but a management system for warehouses turns them into an opportunity for improved service. The system streamlines return processing by identifying the returned product, assessing its condition, and suggesting its next steps—restocking, repair, or disposal.

For instance, judgments can be automated by using pre-established rules for return reasons, and inventory correctness is guaranteed by real-time updates. Reduced operational stress and happier consumers are the results of faster processing.

Warehouse operations go seamlessly when receiving and put-away procedures are done well. Through real-time updates and streamlined workflows, a WMS helps employees complete these duties more quickly.

From verifying arriving shipments against purchase orders to recommending the best places for storage, the system makes sure that no information is missed. Automated guided vehicles (AGVs) and conveyors are examples of automation alternatives that further improve accuracy and speed.

Imagine a situation where products are received, inspected, and stored without any needless hiccups or mistakes—that is the power of the best warehouse management system.

Managing the workforce is just as important as managing inventory. A system for warehouse management provides tools to monitor employee productivity, assign tasks, and even forecast labor needs based on historical data.

By reducing idle time, features like task interleaving guarantee that employees are constantly involved in productive activities. Performance metrics can also be monitored and examined to determine areas in need of training or to recognize and honor top performers.

Imagine having a digital manager who makes sure all team members are productive and efficient.

The core of a WMS is inventory control. Stockouts, overstocking, and shrinkage are reduced by the system's maintenance of real-time inventory visibility.

Businesses can keep ahead of their inventory needs with the help of sophisticated tools like demand forecasting, cycle counting, and safety stock notifications. For example, without human involvement, automated reordering triggers guarantee that essential items are constantly in stock.

The yard and dock, which are sometimes disregarded, are essential components of the supply chain. A WMS streamlines these procedures by coordinating incoming and departing shipments, tracking trailer movements, and scheduling dock appointments.

Real-time updates reduce bottlenecks and guarantee seamless transitions. Automated signals that tell employees when a trailer is prepared for unloading, for instance, could cut down on idle time.

A WMS turns the yard and dock from chaotic spaces into efficient, well-managed spaces that support the smooth operation of the entire company.

In this chapter, we will examine the top advantages of warehouse management system.

Suppose your team no longer gets bogged down with repetitive tasks. The best warehouse management system automates repetitive tasks and facilitates guidance for order picking, packing, and put-away processes, increasing productivity and efficiency.

Your employees can take advantage of advanced picking methods like wave or batch picking so they can cut down on unnecessary travel within the warehouse. This helps your employees to be more productive and speeds up the fulfilment process for orders.

Running a warehouse can be expensive, but the best warehouse management system software helps trim the fat. Forecasting demand, dynamically allocating storage, and automating replenishment ensure resources are used wisely.

You can utilize slotting optimization that reduces handling time and energy costs. This lowers energy costs and saves costs, which allows you to keep inventory in check.

Suppose you can determine your product and what is always available and where. This is made possible via a warehouse inventory management system, which provides real-time inventory adjustments. Eliminating doubt and ensuring that every product is available helps you prevent stockouts, reduce overstocking, and make better judgments.

Mistakes happen, but a warehouse inventory management system helps keep them to a minimum. Tools like barcode scanning and automated checks ensure the right products are picked, packed, and shipped every time.

Think of automated quality checks as your final safety net. They make errors before they become customer complaints, saving time and building trust.

A cluttered warehouse is an inefficient warehouse. Inventory management system for warehouses analyzes your inventory and suggests the best storage configurations. It’s like playing Tetris but with shelves and pallets.

Fast-moving items are placed in easily accessible spots while slower-moving ones are tucked away. This innovative organization not only saves space but also speeds up operations.

Security isn’t just about locks and cameras. The best warehouse management system tracks every inventory movement and limits access to sensitive areas. Permissions and audit trials hold everyone accountable.

For example, role-based access ensures that only authorized staff handle high-value items. It’s peace of mind for your operations.

When orders are accurate and delivered on time, everyone’s happy. The best warehouse management system software makes that happen by streamlining communication and providing real-time inventory and order status insights.

Suppliers get accurate demand forecasts, and customers receive timely updates. It’s the foundation of strong, lasting relationships.

Managing your workforce doesn’t have to be a juggling act. A system for warehouse management tracks productivity, assigns tasks efficiently, and helps you plan staffing needs based on historical data.

Task interleaving, for instance, keeps workers busy with meaningful tasks, reducing downtime and maximizing output. It’s like having a digital supervisor who never takes a break.

A warehouse stock management system doesn’t operate in isolation. It syncs effortlessly with ERP, TMS, and e-commerce platforms, creating a seamless ecosystem that keeps everything connected.

For example, integration with ERP ensures accurate financials while linking to e-commerce platforms, which speeds up order processing. It’s like having all your systems speak the same language, working together to make your life easier.

In this chapter, we will explore the various warehouse management system examples that can help you align your requirements.

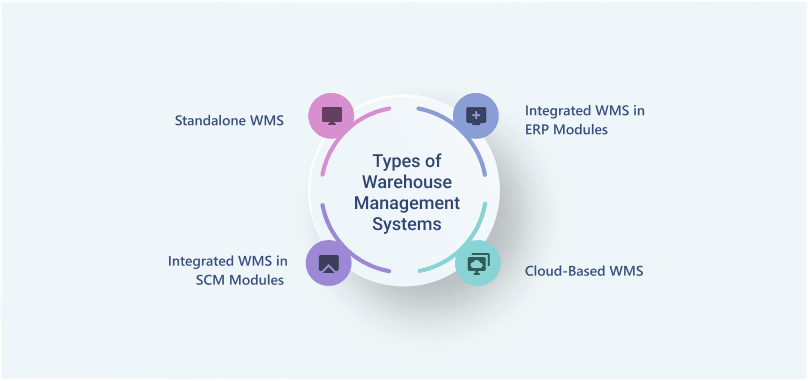

Standalone warehouse management system is perfect for businesses that focus solely on warehouse operations. These systems specialize in tracking stock levels, managing inventory efficiently, and optimizing picking, packing, and shipping processes.

This system helps businesses streamline their workflow without the need for broader integrations. It is ideal for smaller operations or companies with limited technical requirements.

However, the standalone system for warehouse management has limited integration capability and lacks scalability.

Integrated warehouse management system within ERP solutions, such as Dynamics 365 Business Central, provides a comprehensive platform. These systems allow businesses to manage finances, operations, and warehouse tasks in a single solution.

You can gain real-time insights into stock levels and order statuses. These systems provide you with unmatched efficiency and visibility. It eliminates redundant processes and ensures all departments work from the same data set.

However, these systems require higher upfront costs and implementation time.

When WMS is part of a broader supply chain management (SCM) suite, businesses benefit from end-to-end visibility. It offers seamless integration between warehousing and logistics.

However, it is best suited for large enterprises with high implementation and maintenance costs.

A cloud-based WMS allows users to access and manage their warehouse operations without needing to install or maintain any physical hardware on-site. This means you require minimal IT overhead to manage your e-commerce and other business operations.

You can access real-time inventory updates, pay lower upfront costs compared to on-premises systems, and leverage updated & security features.

In this chapter, we will explore the top industries that require warehouse management systems.

E-commerce businesses demand speed, accuracy, and adaptability to thrive in a competitive market. The WMS facilitates real-time inventory updates to prevent overselling. It helps you fulfill orders faster and improves customer satisfaction and retention.

For instance, you can enable batch processing during peak seasons like holidays, which ensures timely and accurate deliveries through route optimization and multi-channel fulfillment.

Logistics companies use WMS to enhance coordination between warehousing and transportation for smoother supply chain management. It helps you streamline transportation processes, improve customer service, and facilitate integration with transportation management systems (TMS).

For instance, you can optimize cross-docking operations to reduce storage time and enable precise route planning for on-time deliveries.

In this chapter, we will explore the top solutions present in the market that will help you manage your warehouse management.

Microsoft Dynamics 365 is a robust solution for companies to manage their warehouse operation. It offers two standout solutions: Dynamics 365 Business Central and Dynamics 365 Supply Chain Management, with specific requirements. Dynamics BC is designed for SMBs, while Dynamics Supply Chain Management is for large enterprises.

These systems seamlessly integrate with other Microsoft tools and provide robust features for inventory management, real-time analytics, and supply chain optimization.

Key Feature for WMS:

SAP EWM is a powerful solution tailored for complex warehouse operations. It supports advanced functionalities such as slotting optimization, cross-docking, and labor management.

You can optimize labor usage, enhance order accuracy, and streamline intricate workflows. You can automate warehouse processes, optimize picking routes, and use efficient labor management to achieve faster order fulfillment.

However, this system has premium pricing, extended deployment timelines, and requires significant resources.

Key Features:

NetSuite WMS is a module within the NetSuite ERP that streamlines warehouse operations and optimizes business processes like receiving, put-away, picking, packing, and shipping.

You can manage your inventory, track transactions, and guide users through warehouse tasks. It enables you to pick items for orders and prepare them for shipment.

However, it has limited offline functionality and requires additional modules for advanced features.

Key Features:

ShipHero simplifies inventory and shipping management for e-commerce businesses. This enables them to scale effortlessly during peak seasons while maintaining accuracy. Businesses can reduce errors, increase efficiency, improve productivity, and decrease warehouse costs.

However, it is suitable for non-e-commerce industries and has limited scalability for enterprise needs.

Key Features:

Inciflo is a WMS software that streamlines warehouse operations, optimizes inventory management, and enhances operational transparency. This solution enables you to manage offline and online sales within a single solution.

You can simplify coordination between warehousing and transportation. However, it has limited customization options and requires a stable internet connection.

Key Features:

Logiwa is designed for fast-paced, high-volume operations, ensuring precision and speed in order processing while simplifying inventory management. It helps you fulfill orders for high-volume direct-to-consumer (DTC) brands, wholesalers, and third-party logistics (3PLs).

However, it has limited out-of-the-box features requiring significant customization and potential limitations for complex warehouse operations.

Key Features:

Zoho Inventory empowers small businesses to manage their inventory, track stock across multiple warehouses, fulfill orders, and streamline warehouse operations effectively.

However, it has limited customization options, restricted third-party integrations, and a limited template library.

Key Features:

With so many options, how do you find the perfect WMS? Here’s a step-by-step guide:

Evaluate your warehouse size, complexity, and operational challenges. Identify must-have features and prioritize them.

Shortlist vendors with a proven track record in your industry. Compare their offerings, customer reviews, and support services.

Choose a WMS that can grow with your business, especially if you’re planning to expand operations or enter new markets.

A live demo can give you a clear picture of the system’s user interface, features, and ease of use.

Look beyond the initial price. Consider maintenance, integration, and upgrade costs over the system’s lifecycle.

With so many options, how do you find the perfect WMS? Here’s a step-by-step guide:

A system for warehouse management can revolutionize how you manage your warehouse operations. By boosting productivity, reducing operational costs, enhancing inventory visibility, and improving customer satisfaction, a WMS transforms your warehouse into a strategic asset rather than just a storage facility. Whether you’re running a small business or a global enterprise, leveraging the right WMS can position your organization for long-term success in an increasingly competitive marketplace.

However, choosing the right solution and going for warehouse management system implementation can be daunting. Thus, Dynamics Square makes the process seamless. As a trusted Microsoft Partner, we specialize in delivering customized solutions like Business Central and Supply Chain Management.

Here’s how Dynamics Square can assist your business: